To give you an idea of how compact the world of fat bikes is, I met the owner of A-Train Cycles, Alex Cook, a few years ago, when I became his very first customer by purchasing a custom porteur front rack for my pugsley. Back then, Alex was working for a bike shop and welded custom racks in the basement under the name B.C. Racks. I still rock that rack and have been following Alex’s fabrication skills expand into some beautifully lugged frames of every cycling niche, via the A-train Cycles web-site and Flickr account. Last January I interviewed Alex at his fabrication studio in Minneapolis, where we met, face to face, for the first time.

FB.C – What are some of the biggest challenges in working with stainless?

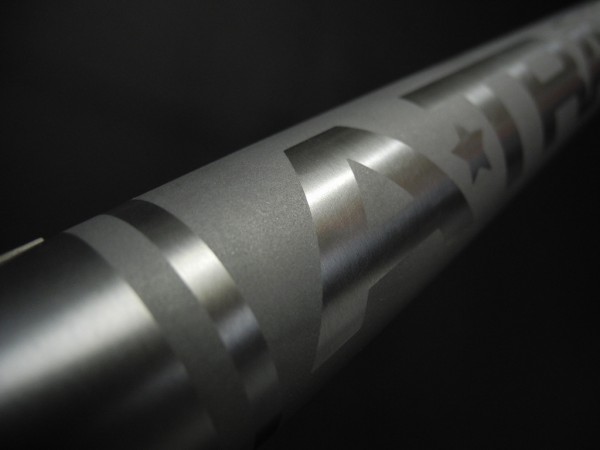

The unique challenges of working with stainless steel require a confidant, steady hand and intimate knowledge of heat application, range, and technique. Even a skilled builder needs to pay close attention or risk overheating and damaging expensive tubes. Because stainless steel is incredibly strong it readily lends itself to thin walls that yield light, stiff, and elegant frames. Unfortunately it also lends itself to excessive tool wear, which requires new hole saws, drill bits, and files for each frame produced. In the end, it’s worth it. The bare, unpainted frame hides nothing of the craftsmanship. However, this level of refinement comes with an additional time investment. Many hard hours are spent meticulously finishing each frame with a jewelers file, sandpaper, and scotchbrite pads.

FB.C – How long until we can see an A-train Cycles stainless fat bike?

Either when I am able to find time to pencil myself into the build queue or until somebody orders one.

FB.C – Do you still make custom racks?

I offer stock front racks for the Pugsley and Enabler forks, as well as fully custom options to compliment frames that I’m building. The word “stock” might be a bit of a misnomer, as they are not “stock” in the traditional sense. Each rack is made to order, entirely by hand, and can altered to fit the needs of the customer. In the A-train Cycles shop you won’t find shelves filled with racks waiting to be shipped or any fancy fixtures designed to expedite production at the expense of the beauty of human ingenuity and craftsmanship. All the racks I build are made with hollow steel or stainless steel tubing because hollow steel racks are both lighter and stronger that their solid aluminium counterpart.

FB.C – But how about racks for a Moonlander?

There is not presently a stock configuration, but if demand increases that may change.

FB.C – What vintage bikes really inspire you?

I am inspired by bicycles of different eras that have redefined the concept of what a bike represents, both in terms of raw capability and aesthetic. The sheer diversity in the market today was fueled by the innovations of small bike companies pushing the limits. This has led to ultra light carbon fiber road bikes, full suspension fat bikes, indestructible German hub gears first assembled in some dude’s garage, and everything in between. More and different bikes will broaden the appeal of the bicycle and result in the greatest thing of all: more people riding.

FB.C – What differentiates A-train from other custom frame builders?

I believe that building a truly custom bike means building it slowly. Rather than rushing through the process, each frame is carefully constructed over the course of weeks rather than days. While I certainly could build bikes faster, I think it would be a disservice to the customer. Details are important. This means frequent communication with the buyer, a precise understanding purpose, and ultimately, a clear vision of the finished product. For instance, if you are planning on riding your fat bike primarily as a commuter on roads I would probably recommend a lower bottom bracket than if your were planning on riding it over downed trees, road bikes, or cars. While vision is critical, so is the commitment to using the finest, most advanced steel and stainless steel tubing available. The combination results in a perfect union of advanced technology and expressive art.

FB.C – What frame builder inspires you?

Dave Anderson– Dave is another frame builder near me in Minneapolis, MN. He does beautiful work and is largely responsible for my obsession with stainless steel. Furthermore he is always willing to share his knowledge of the craft and is genuinely a good guy.

Look for a Reader’s Ride(s) article on Arrowhead 135 racer – Tom Lais, A-Train Fat-Bike coming up later this month – same fat-time – same fat-station – fat-bike.com

No comments yet.